Apple Rubber recently celebrated its 50th anniversary of providing sealing solutions to customers. Over the years, our engineering expertise has grown significantly. Each new project gives us the chance to apply lessons learned from past applications or tackle unique challenges.

One such case involved an o-ring seal used in a dispensing device with multiple pipette tips. The spacing of the plungers was fixed, limiting the size of the o-ring gland. This made it an ideal scenario for employing a MicrOring.

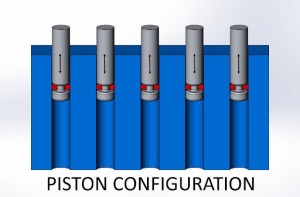

Initially, the designer wanted the o-ring sized for a piston configuration. They asked Apple Rubber Engineering to specify the gland dimensions and the appropriate o-ring size. However, the dimensions provided, with a bore of Ø0.0625” and a piston of Ø0.060”, posed assembly challenges. The required o-ring groove diameter in the piston would be around Ø0.026”, making assembly difficult and creating a thin section prone to failure during reciprocating movements.

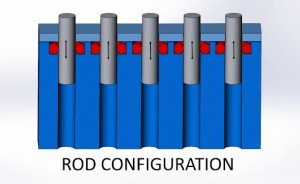

In this application, the piston doesn’t come into contact with the dispensed fluids; it’s solely tasked with displacing volume. Therefore, the recommended solution was to design the seal using a MicrOring in a Rod type configuration. This made assembly much easier, with a precision ground rod providing the necessary tolerances for the MicrOring. Importantly, the rod seal gland fit within the spacing requirements for the multichannel device.

In conclusion, when designing components for assembly, understanding scale and geometry is crucial. MicrOrings offer excellent sealing solutions when attention is paid to assembly, tolerances, and the impact of tolerance stack on sealing components. Apple Rubber offers various engineering resources, including the O-Ring Gland Calculator, to assist engineers and designers. If you encounter challenges beyond these tools, don’t hesitate to contact Apple Rubber directly for engineering assistance.