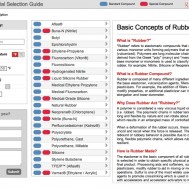

Apple Rubber Products offers the seal industry’s broadest range of products, with sealing solutions available in a wide variety of materials. Over the next few weeks, we will be highlighting our available materials here and giving you valuable information on each compound.

Aflas®

Buna-N (Nitrile)

Butyl

Epichlorohydrin

Ethylene-Propylene

Aflas is a copolymer of tetrafluoroethylene/propylene. This material offers a combination of high temperature and chemical resistance. The standard compound of Aflas® has a temperature range of -14° to +446°F, and a Hardness (Shore A) of 60 to 90.

Aflas is used mainly in seals for oil field, aerospace, chemical and general industrial environments.

Buna-N (Nitrile)* is the seal industry’s most widely used and economical elastomer. Nitrile combines excellent resistance to petroleum-based oils and fuels, silicone greases, hydraulic fluids, water and alcohols, with a good balance of desirable working properties such as low compression set, high tensile strength, and high abrasion resistance.

Buna-N (Nitrile) is commonly used in low temperature military uses, off-road equipment, automotive, marine, and aircraft fuel systems. The temperature range of the standard compound is -40° to +257°F, and of the special compound is -76° to +275°F, with a Hardness (Shore A) of 40 to 90.

Butyl is an all-petroleum product; a copolymer of isobutylene and isoprene that has largely been replaced by Ethylene Propylene since its introduction. This material has an outstanding low permeability to gases, and is especially effective in vacuum sealing applications.

Butyl is often used in seals for hydraulic systems using synthetic fluids. The temperature range for the material is -50° to +250°F, with a Hardness (Shore A) of 30 to 90.

Epichlorohydrin is mainly used for fuel and air conditioning system components, as well as in the petroleum industry where a higher temperature capability is required. Epichlorohydrin features excellent resistance to hydrocarbon oils and fuels; low solvent and gas permeability; excellent resistance to ozone and weathering; and stable cycling from low to high temperature.

Epichlorohydrin has a temperature range of -40° to +275°F, and a Hardness (Shore A) of 50-90.

Ethylene-Propylene has gained seal industry acceptance for its excellent ozone and chemical resistance characteristics. This material is mainly used in outdoor weather resistant uses, automotive brake systems, automobile cooling systems, water applications, and low torque drive belts.

When compounded using peroxide curing agents, Ethylene-Propylene high temperature service can reach +350°F. Average temperature range for the standard compound is -40° to +275°F, for the special compound is -76° to +302°F, with a Hardness (Shore A) of 40 to 95.

For more information on any or all of these materials, take a look at our Material Selection Guide at www.applerubber.com/material-selection-guide/

*Special Compound