Transfer molding is one of the many ways that engineers manufacture rubber parts. Before the process takes place, the appropriate amount of molding material is measured, inserted and placed into the molding pot. As the material is heated, pressure forces it to transfer into the mold cavities.

The Transfer Molding Process

1). A piece of uncured rubber is placed into a portion of the mold.

2). The mold is closed up and under hydraulic pressure, the rubber is forced through a small hole into the cavity. The mold is held closed while the rubber cures.

3). The plunger is raised up and the transfer pad material is removed

4). Mold is opened and the part can be removed. Any flash is trimmed and removed during this time.

Transfer Molding Applications: What is it used for?

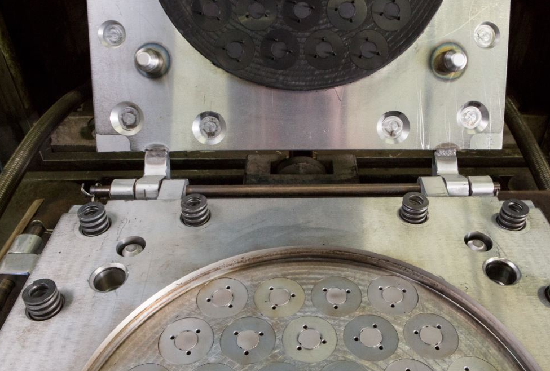

Transfer molding is a great way to create composite seals with insert molding — which “float” in the cavity. Since cavities are independent of one another, they can move freely rather than being cut directly into the same plate. This helps to absorb variations in tolerances, so the mold will stay consistent.

Various inserts like plastic and metal can be used to make the composite seal. These allow for a multi-component sealing solution, helping reduce overall component count in assembly and providing a more robust seal.

- Natural gas industry: Metal to rubber face seals are used in the natural gas industry to create interface for gas valves.

- Electrical industry: Wires are inserted into cavities to mold connector seals around the wire. The must common are spark plug wires.

- Hydraulic Industry: Transfer molding allows for sharper cutoffs during molding, which is a major advantage to lip or U-cup designs in the hydraulic industry. A more defined lip edge can lead to sharp lip seals and almost flash-free parts.

The Advantages

1). High Cavity Count. In many cases, transfer molded rubber products require few and simple pre-forms. One pre-form can fill hundreds of cavities. This is an advantage over compression molding, and can save a significant amount of time in the molding process. This is also an advantage over injection molding since there is not a runner to fill each cavity reducing the number of cavitiess.

2). Design Flexibility. Transfer molding allows for sharper edges. Micro grind vents reduce the need for overflows allowing for near flash less parts, greatly reducing deflash process or allow flash limits to directly ship parts. With pot and plunger design, simplified preforms required allowing for standardization and lower cost.

3). Short production cycle. Transfer molding offers shorter cycle times than compression molding and can provide more consistency, too. The process allows for tighter tolerances and more intricate parts.

The Disadvantages

1). Complex molds. Since the design and mold tends to be complex, tooling can also become expensive.

2).Waste material. Transfer pots typically produce higher volume waste than traditional overflows in compression tools. Transfer molding typically produces a large pad with sprues. The scraps are not reusable, since the polymers are thermosetting.

3). Mold Maintenance. Inserted transfer tools require more mold maintenance than compression tools. Typically, inserts have to be taken out and reset to maintain movement over time. Cleaning the tool can be time consumering, and sometimes special equipment like dry ice blasters are used to clean the intricate transfer insert.

How does transfer molding affect your processes? We’d love to hear your thoughts on Twitter. Connect with @AppleRubber!