Tolerance stack-up is a very important factor when it comes to O-rings. Why? In a sealing application, the tolerances of all parts in contact with the O-ring MUST be considered in order to create an effective seal.

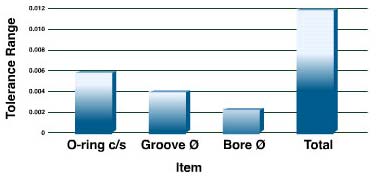

In the graph above, the O-ring cross section tolerance is (+-).003”, the groove diameter tolerance is (+-).002”, and the bore diameter tolerance is (+-).001”.

In this specific example, the metal dimensions and the O-ring can vary up to (+-) .006”. Because of this, the total tolerance stack up is .012”. If the nominal O-ring size is .030”, it is easy to see that the tolerance stack-up is nearly half the size of the O-ring.

When a situation like this happens, it will result in either too much or too little compression and can cause the O-ring to fail.

If you are utilizing a standard size O-ring, is it usually possible to compensate for tolerance stack-up. You can compensate for this is a number of ways, including the specification of a larger O-ring. Unfortunately, in microminiature applications, there is little room for this type of compensation to occur.