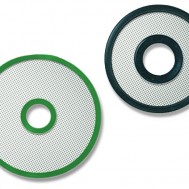

From food-grade applications to the automotive industry, efficient sealing solutions are always required. To meet growing demands in a wide range of industries, Apple Rubber designed the Filter Seal®, a combination of elastomer and fabric, metal or plastic that works as both a filter and seal in one device. Since the advanced sealing technology was pioneered over a decade ago, Apple Rubber has produced more than 10 million custom Filter Seals® for a variety of applications.

Here’s what you need to know about Filter Seals®:

Filter Seals® are a quick fix.

Filter Seals® provide a simplified solution for applications that require both a rubber seal and filtration. The multi-functional seal is compact and requires only one part for effective filtration, rather than two or three separate devices. Since only one part is required for purchase and installation, Filter Seals® will save customers money and time, making them an efficient option for any application.

Apple Rubber completes all engineering in-house, to speed design. With our vast knowledge of seal design, we can find the right rubber material to match the correct filter material for your application.

Filter Seals® come in a variety of shapes and sizes.

In order to meet the demands of customers with a wide range of application requirements, Filter Seals® can be manufactured in a variety of different shapes and sizes. Some of the most unique include:

- Oversized Filter Seals® with dual mesh fabric can be used for industrial vacuum applications

- Filter Seals® featuring a metal screen in a composite seal design is used for both I.D. and O.D. filtration in oil applications. Metal is used to ensure durability and chemical compatibility with oil

- Medical-grade silicone with high precision tolerance is used for Filter Seals® in the medical industry. These seals come in unique shapes to fit various medical devices

- Filter Seals® for applications that include valves and ports have small filtration holes running through to keep contamination out of small orifices

Apple Rubber offers custom designs.

From swimming pools to oil applications, every sealing solution requires unique specifications. To provide tailored solutions for difficult sealing applications, Apple Rubber can customize any Filter Seal® to match consumer needs. All Filter Seals® can be crafted in typical elastomeric materials, including silicone, fluorocarbon, nitrile, ethylene-propylene and many more.

To ensure the seal fits properly, Filter Seals® can be designed in virtually any shape or size. To find out what kind of seal would work best for your application, visit the O-Ring Material Selection Guide.

Engineered in various fabric and weave types.

Along with customizing the rubber seal, filtration fabric and weave is also customizable. Filter Seals® are available in polyester, plastic, nylon, stainless steel and brass. Based on the application, the fabric and weave can be chosen to handle the type of filtration you require.

The engineers at Apple Rubber take many factors into consideration when selecting a fabric and weave type for your sealing solution. Some of these include filtration requirements, chemical compatibility, corrosion resistance, the burst strength of fabric, fabric flexibility and tensile strength. Based on these determining elements, Apple Rubber engineers will customize Filter Seals® to match the durability and compatibility of the sealing application.

Want to talk more about Filter Seals®?

Tweet us @AppleRubber to continue the conversation.