The Internet of Things is set to improve efficiency, streamline supply chain management and revolutionize business for several industries — but no industry will experience more benefits of this new network of technologies than the manufacturing sector.

What does this era of deep data inter-connectivity mean for the future of manufacturing?

The Internet of Things: Who’s Connected?

The IoT refers to the practice of connecting objects, appliances, buildings, and equipment to the web — and it’s already a significant factor for major industries, particularly manufacturing.

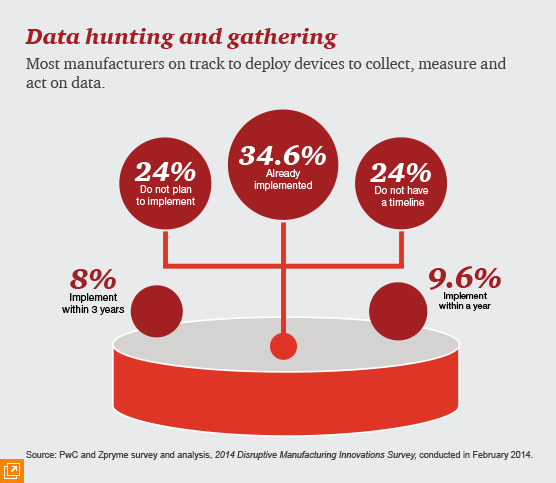

According to a PwC survey, manufacturers fall roughly into one of three groups: early adopters, sideliners (doing little or nothing), and waders (those beginning or planning to begin to adopt). Some key findings include:

- 35 percent of US manufacturers are currently collecting and using data generated by smart sensors to enhance manufacturing/operating processes

- 34 percent believe it is “extremely critical” that US manufacturers adopt an IoT strategy in their operations

- 38 percent currently embed sensors in products that enable end-users/customers to collect sensor-generated data.

Key examples by industry:

Industrial: Almost one-fifth of major manufacturing companies are already using the IoT to increase production and reduce costs. Plastics manufacturer Petrobas Zarate of Argentina added sensors to the factory to monitor the temperature so it could ensure the plastic was created under optimal conditions.

Automotive: 17 percent of automotive companies are using IoT devices in the production of their vehicles. Volkswagen added an SAP system that keeps track of all of their parts’ supply pipeline to help them track where items are located at all times.

Aerospace: The IoT is revolutionizing the aerospace industry, transforming every part of the sector — from assembly and manufacturing to maintenance and safety, including tracking the aircraft’s location. Distributed sensors now monitor key performance parameters such as fuel burn in the engine. When the flight has landed, this information can be downloaded and analyzed by the ground staff, enabling appropriate action to correct any minor faults or alterations to get the aircraft back in service as soon as possible.

What to Expect from the IoT’s Future

The IoT has already taken manufacturing to a whole new level, but its benefits may not be utilized across the entire manufacturing sector just yet. For those still learning about its technology, here are some IoT trends you can count on:

Decreased safety hazards. Sine-Wave, a company that focuses on technological solutions for businesses, has created a customized IoT program that resulted in increased safety and communication in mines. According to their website, they designed a browser-based application that allows users to communicate with the workers, operators, and machines in the mine, as well as “see a real-time view of all activities underground [including] custom mapping of each mining operation.” By knowing what’s going on in the underground mines in real time, users can avoid safety hazards and respond to emergencies quickly.

A shift in manufacturing talent. With an emphasis on STEM skills, big data and the Internet of Things, the manufacturers will aim to hire individuals with the analytical and mathematical talent necessary for the job. Analytical talent is becoming increasingly rare in the labor market, so there will be fierce competition in this industry.

“With all this new information available—about interdependencies, the flow of materials, the cycle time, and so on—manufacturers can lower their inventory costs and reduce the amount of capital required,” suggests Siegfried Dais, former deputy chairman of Robert Bosch. “But don’t forget: this involves huge amounts of data, and the fundamental prerequisite for such a system is that it is stable and reproducible. Common sense won’t help here; this involves rigorous mathematics.”

Operational excellence and improved productivity. According to the Aberdeen Group, 70 percent of manufacturing executives are focusing on plant-floor data initiatives to drive operational and business excellence, faster time to market and immediate access to data from machines on the factory floor. Tapping the potential in a new generation of networking and analytical platforms capable of processing vast streams of industrial data will spur integration, collaboration and creativity.

Manufacturing and The Internet of Things

“Of all the manufacturing technology trends that are taking place right now, perhaps the biggest one is the Internet of Things;” notes Daniel Burrus, CEO of Burrus Research and one of the world’s leading technology forecasters. “It’s the one that’s going to give us the most disruption as well as the most opportunity over the next five years.”

Has your organization implemented IoT technologies? What types of changes is your organization experiencing? We’d love to hear your thoughts — connect with us on Twitter @AppleRubber or contact our engineering team.