During the molding process, elevated temperatures and pressure are used to vulcanize (or “cure”) the rubber compound in the mold cavity. The resulting o-ring (or other rubber shape) is, at room temperature, smaller than the cavity that was used.

This difference between the thermal expansion of the mold material — typically steel — where the cavity is machined and the rubber compound results in a “shrink rate” calculated as:

shrink rate = (cavity dimension – part length) / cavity dimension) [typical units in/in]

This shrinkage value is applied to the desired finished part size to “scale up” the cavity. The resulting cavity dimension is calculated as:

Cavity Dimension = finished part length / (1- shrink rate)

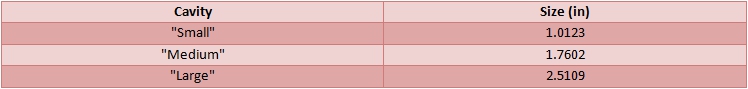

For example:

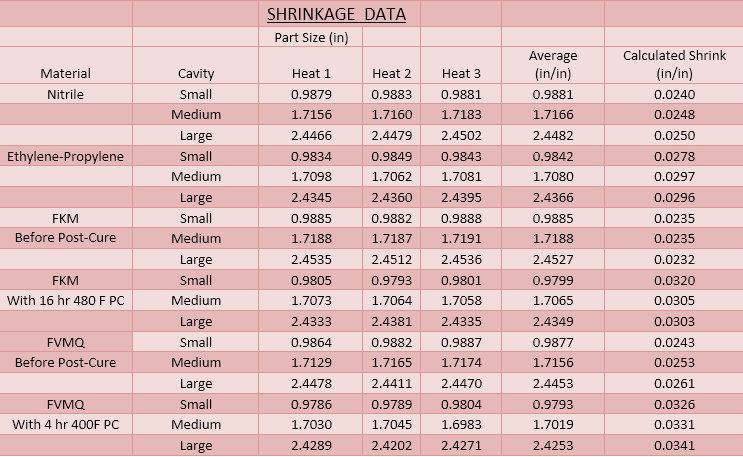

Shrinkage rate testing was performed on a 70 Shore A Nitrile (Buna-N), Ethylene-Propylene (EP), Fluorosilicone (FVMQ), and 75 Shore A Fluorocarbon (FKM). The Fluorosilicone and Fluorocarbon materials undergo a secondary vulcanization process called post-curing.

During the post-curing process, the molded parts were baked in a ventilated oven at a specific time and temperature recommended by the material manufacturer, or at a temperature greater than the service temperature of the final application.

This was done to drive off any residual volatiles (processing additives, curing catalyst) resulting from the initial vulcanization process. These volatiles must be eliminated to mitigate potential outgassing that can be a source of contamination in food, medical, electronic or other sensitive applications.

An important note — post-curing also promotes further cross-linking of the elastomer’s polymer chains, which results in improved physical properties like tensile strength, elongation, compression set resistance, chemical resistance, and, for this focus, additional shrinkage.

The following picture shows the steel transfer tool with a “small,” “medium,” and “large” cavity of known sizes, and three separate heats of the molded fluorosilicone material. Each of the sizes were measured, and the corresponding shrink rate was calculated and averaged for each size.

The table below shows the cavity dimensions, finished part measurements and the calculated shrink rate.

Material shrinkage is not always easy to predict, and there are several factors that can affect the shrink rate of rubber. Primarily, the molding method — in conjunction with processing — has the most influence. Molding methods include compression, transfer and injection. Each method of rubber delivery to the cavity shears the compound at different rates affecting the viscosity, flow, polymer orientation, and, ultimately, the shrink when the rubber part is vulcanized.

Typical processing adjustments include temperature, time, pressure (injection and clamp), and speed. Higher mold temperature can lead to more pronounced shrink rates due to the thermal expansion of the mold material.

Even part geometry and shape can affect how much, or how little, specific features of the finished part actually shrink.

Shrinkage may also be affected by additives such as curatives, fillers or lubrication. Peroxide-cured material, for example, can have a higher shrink rate then sulfur-cured systems.

In certain circumstances — because of the sometimes unpredictable nature of shrinkage — building a prototype may be warranted. The prototype would be tested under conditions as similar as possible to what would be seen in a production environment. This is meant to validate the molding process and check the finished part sizes. Appropriate adjustments to cavity size are then made if required.

Prototype tooling can be done from simple O-rings tools to highly complex insert molds. Small production tooling can also benefit the customer because it allows parts to be tried in the actual design to assure proper fit before creating larger cavity production tooling.

If all goes well, the finished part will dimensionally fall in the specified tolerance range.