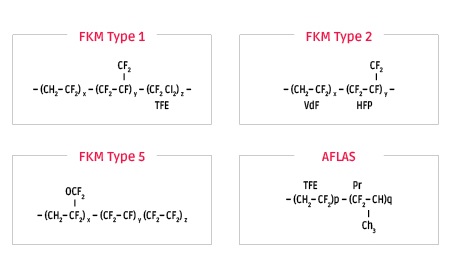

AFLAS® has been around since 1975. This polymer is similar to FKM polymers and is listed under ASTM D1418 as FEPM. Typical advantages of AFLAS® include excellent heat resistance for continuous service to 200’C and unmatched resistance to base resistance. For FKM polymers, the VdF chain is attacked by bases or amine type materials. Disadvantages of these polymers include compatibility with gasoline or light fuel oils.

AFLAS® also have excellent electrical resistivity. Variations in fillers and formulations can change numbers. Present numbers are just based on standard formulations.

Table 1: Electrical Properties of polymers

AFLAS® also shows excellent radiation resistance with stability up to 200MRAD of gamma-ray radiation.

Compunding

AFLAS® is mixed by conventional means as typically rubber compounds. Banbury and open mill mixing are used. All means of processing can be performed: press molded, injection, transfer, extruding, and calendaring.

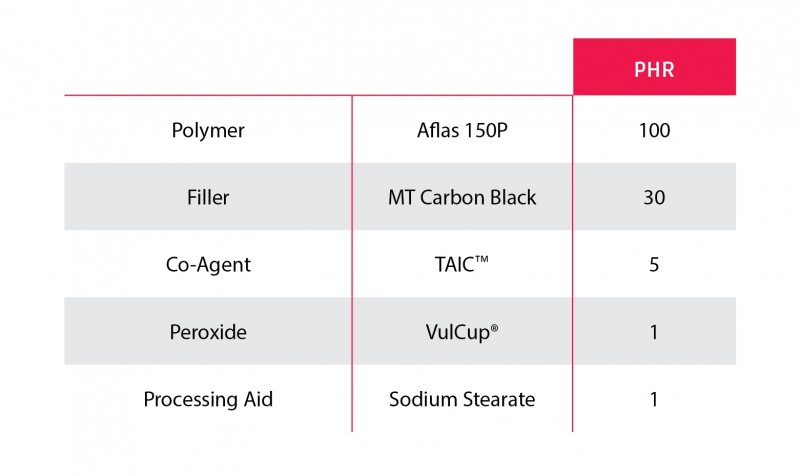

Below is the typical formula for 75 durometer black AFLAS®.

Table 2: Formulation

There are various AFLAS® polymers that offer processing or physical improvements. AFLAS® 150L is a lower viscosity polymer to help with extrusion or improved mold flow. AFLAS® 100S is a high viscosity polymer that helps with explosive decompression for downhole applications.

Rubber to Metal Bonding

AFLAS® works well as shaft seals, cylinder head gaskets or oil seals that are bonded to a metal. Since AFLAS® provides solvent, ozone and steam resistance, compounds work very well in oil and gas exploration, chemical processing and automotive seals. A good bonding agent for a one-coat clear adhesive to carbon steel is MEGUM W-2525. Evaluations with AFLAS 600X and AFLAS 100S achieved 100% rubber retention and high peel strength to both grades.

New Products

To complete with other FFKM materials. AGC Chemicals developed AFLAS PM-1100 and PM-3000. These are fluoroelastomers derived from tetrafluoroethylene and perfluoroalkyl vinyl ether. These polymers can take continuous service temperature to 230’C and 250’C respectively. They are both suitable for extremely harsh and aggressive chemical environments.

Recommendations

AFLAS® is a very good polymer for sealing applications. When specifying material on a part print, you will want to avoid using the exact polymer name. Work with your seal provider to get the right formulation for your project. Locking a processor to a specific polymer may not get you the correct material or limit their ability to mold a part. Compounders may use a combination of polymers to improve processing while maintaining the correct physical requirements. In addition, new advancements in polymers provided by AGC give formulators new tools to make compounds even more robust for their customers.

We have replaced costly seals made from FFKM like Kalrez®. Certain chemicals will break down standard FKM (Viton®), so users typically choose FFKM for better chemical resistance. In these cases, AFLAS® may provide sufficient resistance to the chemical used. This will provide a much more economical solution than an FFKM can provide. Check with your seal provider or research chemical guides to see how the chemical your seal is exposed to will work with all types of polymers, especially AFLAS®.