Fluoropolymers are commonly used in rubber seals because of their excellent resistance to solvents, acids and bases. During the production process, harsh chemicals such as perfluorooctanoic acid are commonly used to elevate resistance properties. However, these chemicals can leave lasting effects on the environment and can be harmful if not properly regulated.

One well known fluoroelastomer, known as FKM or Viton™, is commonly used across all industries. These rubber compounds produce one of the best chemical and high-temperature resistance materials of all the rubber families. FKM rubber can be molded into o-rings, hydraulic seals, U-cups, and custom shapes.

What is Perfluorooctanoic Acid?

Perfluorooctanoic Acid (PFOA) is used worldwide as an industrial surfactant, which means it produces a surface acting agent. PFOA was commonly used in the production of perfluorochemicals (PFCs), and was a byproduct in producing fluoropolymers. PFCs are chemicals used to make fluoropolymer coatings and products that resist elements such as:

- Heat

- Oil

- Stains

- Grease

- Water

This acid is often found in fire-fighting foams and repellents for water and grease in the textile industry.

Additionally, PFOA was a critical part in the production of a common fluoropolymer called Teflon™, but since 2002, manufacturers incorporated new processes that did not require this chemical. Manufacturers have decided to stay away from PFOA because it does not break down in the environment and has been identified in bodies of water and in both land and sea animals.

To combat the potential dangers of PFOA, the European Commission has introduced (EU) 2017/1000, which regulates PFOA and its salts. It requires limits to PFOA and its salts do not exceed 25 parts per billion (ppb) and 1,000 ppb in one or a combination of PFOA-related substances. This restriction became applicable on July 4th, 2020.

Should PFOA be present in Viton™?

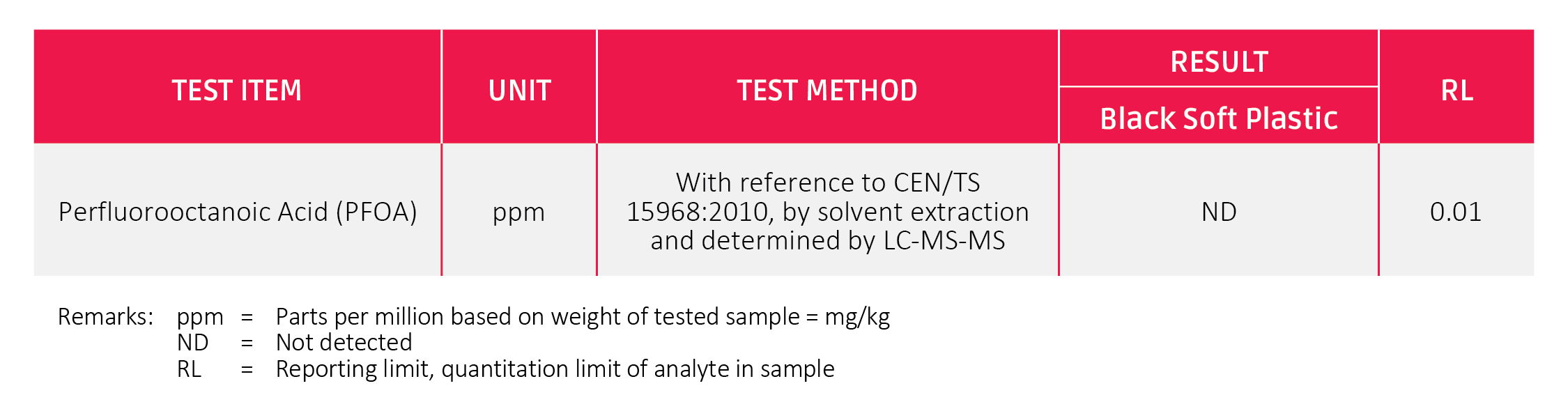

Although Viton™ is considered a fluoropolymer, PFOA was not used in the production of this polymer. Thus, there should be no trace amount of PFOA found in Viton™ at all. To verify this, Apple Rubber selected various samples of compounds from multiple suppliers and of different grades. Samples were processed with standard molding conditions and post cures, which are used on our finished goods. This method was chosen to duplicate the conditions on which our customers would receive their finished parts. Test samples were sent to Intertek for testing.

The above results were found in all eight samples that we sent. PFOA was not detected in any of the samples. This gives us the confidence that we can provide FKM finished goods with no PFOA present.

FKM rubber is an important sealing material in chemical and automotive applications. These industries rely on safe, effective and regulated seals to ensure their products are handled properly. By testing our FKM samples for PFOA, our customers can feel secure knowing that PFOA will not have an impact on their applications or products.