When companies request custom material specifications for O-Rings, a common question arises: What is my tolerance supposed to be?

Unlike tolerances for standard AS568 O-Rings, this can be somewhat of a gray area.

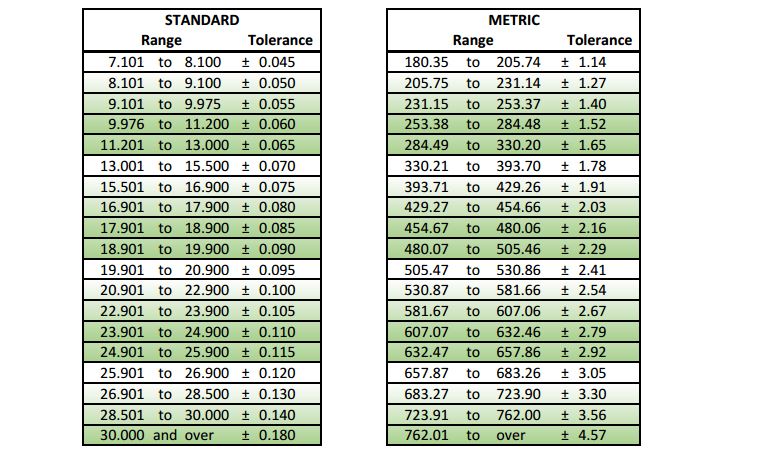

Standard O-rings (or ISO 3601), are given a concrete, set tolerance for both Inner Diameter (ID) and Cross Section (CS). For non-standard O-Rings, however, there is no industry standard for this –several dimensional specifications have to be taken into consideration. Since Apple Rubber stocks over 8,000 sizes and material combinations, coming up with a tolerance for these sizes is a top priority for us.

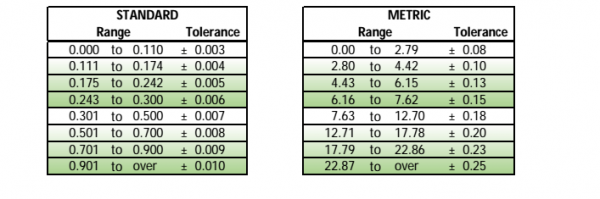

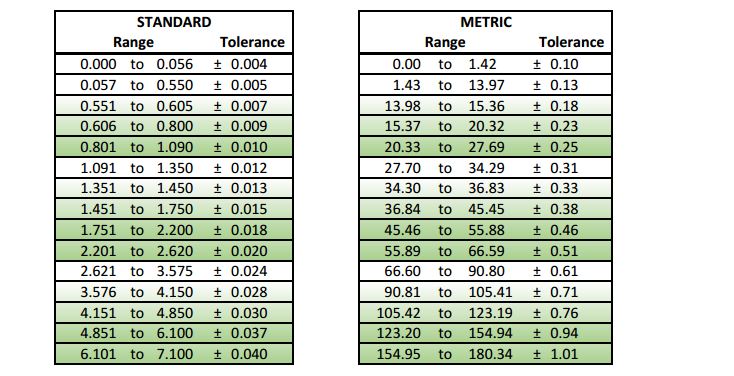

Below is our Quick Reference Guide , which is designed to provide dimensional specification for Non-Standard (or Non-AS568) O-Ring Sizes.

The Non-Standard tolerance can also be used in conjunction with Inspection Specifications. These specifications can be used to put limit on additional standards for rubber defects — such as foreign material, non-fills, and parting line projection. Each specification lists known standards and their respective maximum allowable defect. A tighter level of inspection may result in a higher cost from quality labor, but precision is a guarantee.

If you have any questions in regards to standard or non-standard tolerance, feel free to leave a comment below or connect with us on Twitter @AppleRubber.