At Apple Rubber, various methods of quality testing are conducted using ASTM standards to ensure that our materials and parts are made to specification. One material property that we test is specific gravity, which is used to calculate a material’s density. Following ASTM D297 guidelines, a pycnometer, by hydrostatic readings or by compressed volume densimeter, can be used to determine the density of the given material.

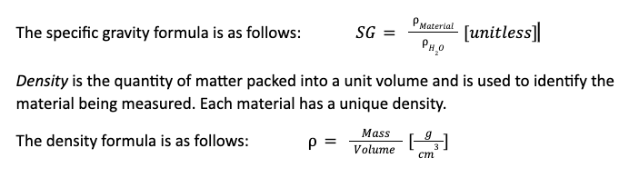

Specific gravity or relative gravity is a dimensionless quantity that is defined as the ratio of the density of a substance to the density of water.

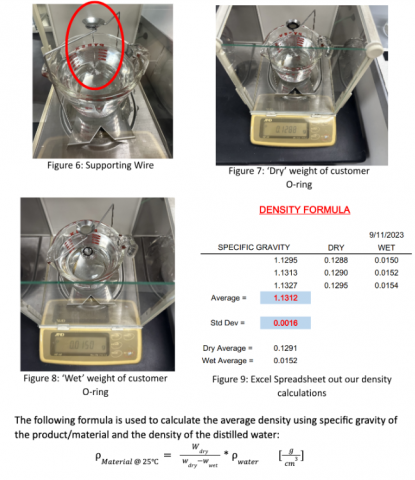

Hydrostatic Method: Apple Rubber uses the ‘Hydrostatic Method’ to determine the density of the materials we are using to make o-rings, gaskets and other parts for our customers. Our set-up is the following:

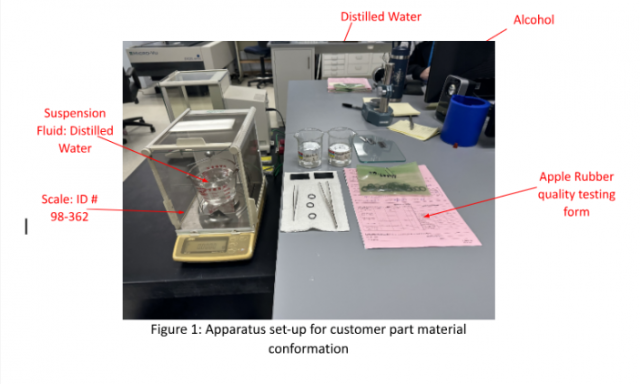

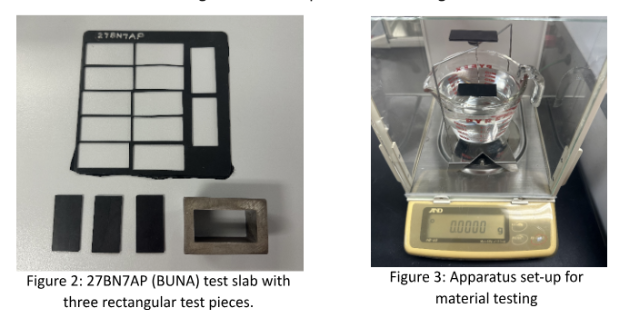

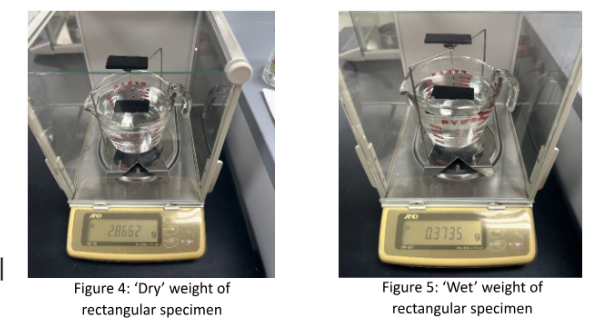

For material testing: Three identical rectangular pieces are cut from a test slab to perform the density measurements. Using our hydrostatic method set-up, we first weigh the specimen in air – to the nearest 1 mg. The ‘dry’ weight of the three samples are recorded. Note that additional rectangular pieces are on the starting apparatus to ensure that the entire weight of our test specimens are being measured.

Following the measurements of specimens in air, the specimens are dipped in alcohol and then dipped in distilled water before being suspended, which aids in eliminating the air bubbles that cause errors in the density determinations. The specimens are then suspended on a fine wire in distilled water, weighed, and recorded into an excel spreadsheet for density calculations.

For product testing: The procedure is identical to material testing, however there is no need to begin with rectangular pieces on the apparatus because in most cases the entire part will fit on the supporting wire. Once the density is calculated, the density of the molded product is compared to the density of the material to ensure the product was made with the correct material.