ASTM D395 is the standard testing method for Compression Set. Based on this method, compression set is defined as the residual deformation of a specimen that was deformed to a specific amount for a given time and temperature. Simply put, it’s the amount of height lost when an o-ring or test button is squeezed for a certain amount of time at a specific temperature.

ASTM D395 Standard Testing Methods for Rubber Property

Based on testing standards, there are usually two different ways that rubber properties can be tested:

Test Method A uses a constant force, typically done with a spring. Method A is rarely used for qualification testing.

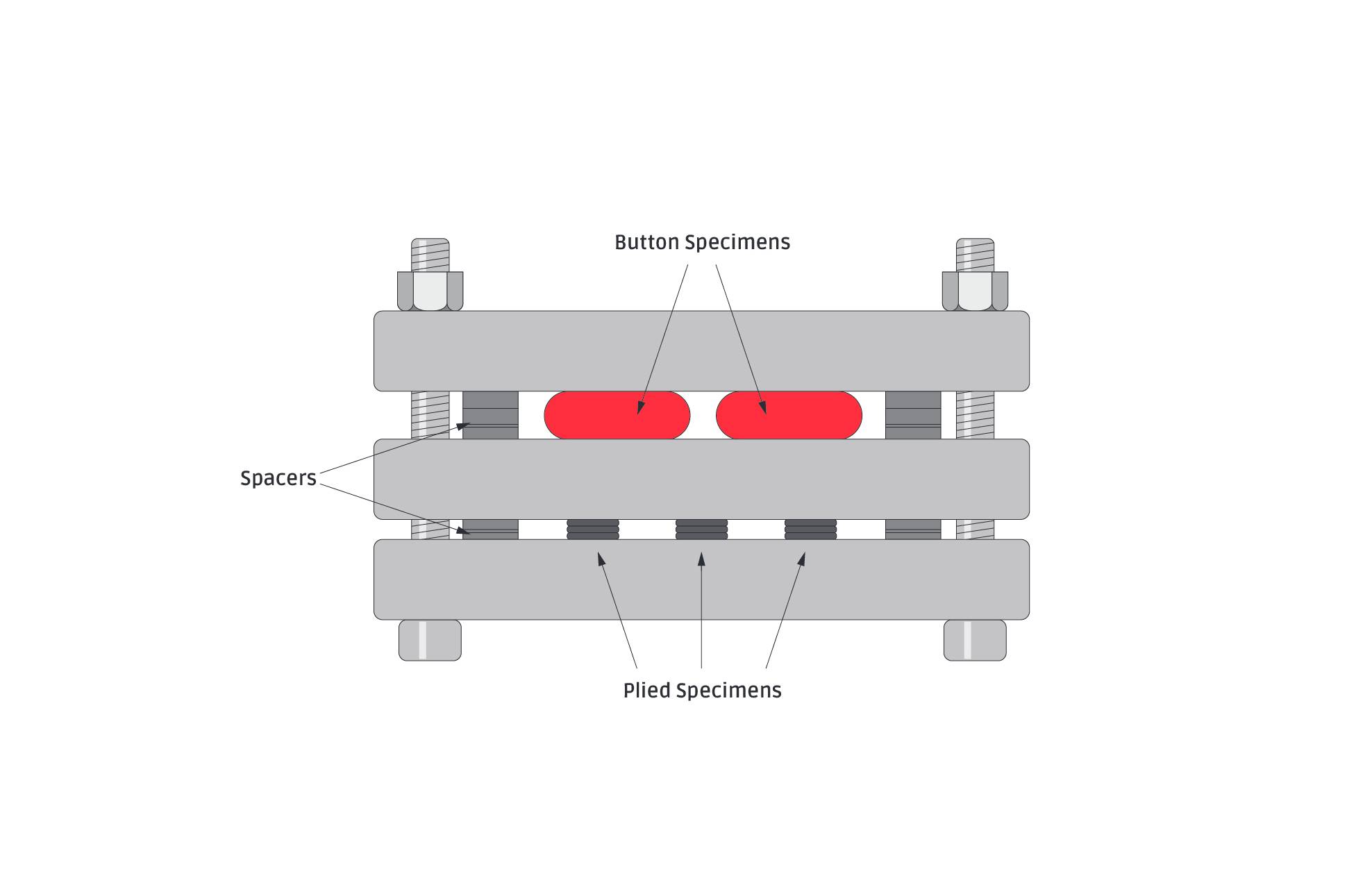

Test Method B uses constant deflection. This method uses a fixture with parallel plates and spacers to create a given deflection. As shown below, screws are used to apply the load and spacers are used to fix the percent compression, which is typically 25%.

The Best Option for Testing

Option A uses a rubber specimen that is molded into a 1.14-inch diameter and .49-inch thick cylinder. This usually provides the best compression set value. Option B uses multiple disks cut from the same test slab. Three stacks of .080-inch thick-cut samples are stacked up to create a .24-inch thick and 0.51-inch diameter. ASTM D1414 is the standard testing method for rubber o-rings. This is essentially the same procedure as test method B, with the exception that the rubber samples are cut from o-rings and deflection is based on the cross-section of the o-ring.

Testing Using Multiple Cross Section Of FKM (Viton™) O-Rings

For this example of testing, a 75 Shore A Black FKM formulation was applied using the Viton ETP™ polymer. This polymer is used for applications in which high chemical resistance is needed. Viton ETP™ offers similar chemical resistance compared to using an FFKM or perfluoroelastomer. This polymer is peroxide cured, so it usually gives a higher compression set than a standard 67% fluorine bisphenol cured compound. Compression testing was performed with 25% deflection and exposed to 200℃ for 22 hours. Samples were taken out of the oven and allowed to rest for 30 mins without the deflection force applied.

Test Results

| Viton ETP 75 Shore A Compound | |

| Cross Section (in.) | Compression Set After 22 Hours @ 200°C |

| 0.070 | 34% |

| 0.103 | 36% |

| 0.139 | 30% |

| 0.210 | 31% |

| 0.275 | 29% |

| Plied Disks | 31% |

| Test Button | 26% |

The results are what is to be expected. As you can see, the test button has the best result. Smaller cross-section o-rings will have a slightly higher compression set. As the cross-section gets larger, the compression set is smaller and closer to the test button. This shows that standardized testing is a good indication of how the o-ring will perform without performing qualification testing on the actual o-ring.