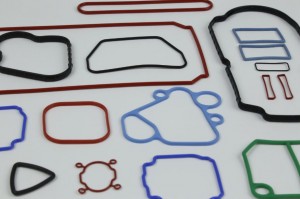

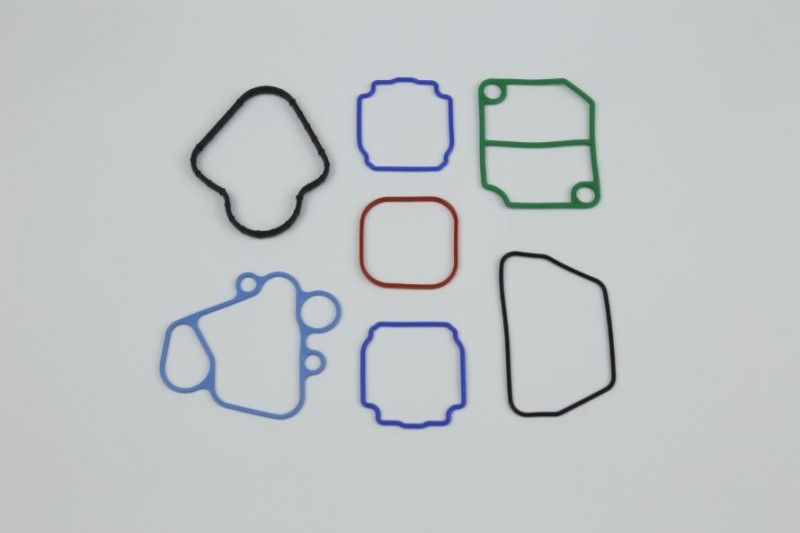

For customers who require custom molded shapes and/or housing seals, Apple Rubber uses a go/no go gauge to better ensure that they’re receiving quality parts that meet their dimensional requirements.

A go/no go gauge is typically a complex shape that duplicates the shape of the required rubber part milled out of metal. It’s an integral part of the quality process that is used to ensure interchangeability of parts between processes or different manufacturers. Instead of returning an actual size or measurement, it returns a state which is either acceptable (go) or unacceptable (no go).

When to use a go/no go gauge

Situations that require the manufacturing and use of a go/no go gauge are:

- Custom molded shapes and housing seals that do not retain their shape outside their intended housings.

- Complex shapes that have dimensions that are unobtainable using one of our noncontact measuring device.

- Parts that are too large for our noncontact measuring device to measure.

Measuring complex rubber shapes

Trying to measure complex parts can be problematic. Because rubber is flexible, any movement of the part can change the dimension trying to be measured. Softer durometer material amplify this problem. Dimensions being measured would be more reliant on how the operator places the part on the measuring system, instead of actual part dimensions. It’s also common to see designs that will dimension to center points or centerlines that cannot be measured on an optical comparator.

Use of a solid fixture allows for more repetitive measurements. Go/no go gauges are produced in the same fashion as the mold for the part being manufactured. Aluminum can be used for ease of cutting. Most of the time they are cut at the same time as the mold, which means no time is wasted when the parts reach our quality control lab.

The go/no go gauge is produced from the customer’s provided print or 3D drawing. The gauge is cut using the upper and lower tolerances of the rubber part. These tolerances allow for slight variations that are found in rubber processing, but within application specifications.

When the customer’s parts reach the quality control lab, they should simply drop into the groove of the gauge. Any overlap or forcing of the part into the groove will tell the lab techs that the part does not meet the customer’s dimensional requirements and steps will be taken to rectify the situation.

The go/no go gauge is a useful tool to ensure that the customer is receiving parts that meet their dimensional requirements. It removes the variable of aligning a custom molded shape or housing seal to be measured with a noncontact measuring device and replaces it with accurate and repeatable results.

What challenges have you come across while measuring complex rubber parts? Let us know. Connect with us on Twitter or LinkedIn or contact our engineering team for assistance.