O-Ring seal applications are categorized in terms of relative motion. In situations involving little or no motion, the application is static. In situations involving reciprocating, rotating, or oscillating motion, the O-Ring application is dynamic.

Let’s dive into the world of static seal applications.

Static seals are categorized as seals whose mating gland parts do not move relative to one another. There is no motion in the sealing surface between the seal and gland.

Static Axial Seals

A static axial seal is one in which there is no motion and the sealing occurs parallel to the seal center-line. The sealing occurs on the top and bottom of the seal, aka the face of the seal.

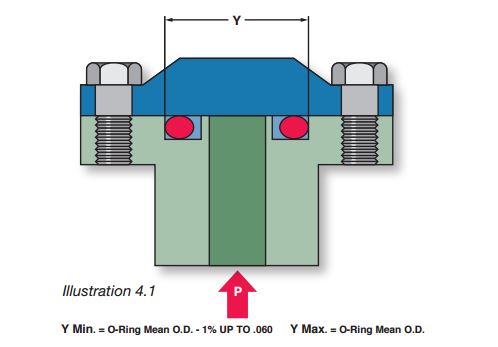

A face seal (Illustration 4.1) is a type of static axial seal. It seals on the face of the seal. A groove is cut in a flat surface (green). The o-ring (red) is placed in the groove and a second flat surface compresses the oring (blue). This is a static application. The o-ring does not move once it is installed.

Illustration 4.1 shows a system with internal pressure. This system pressure will push the o-ring towards the outside diameter of the groove. This outside groove diameter should match the nominal o-ring outer diameter. This will minimize the o-ring shifting in the groove. This outside groove diameter becomes the datum and the inner groove diameter is varied to attain the proper groove width. Conversely, when the system has external pressure, the o-ring will be pushed into the inner groove diameter. The inner groove diameter will become the datum and the outer groove diameter will be the groove width.

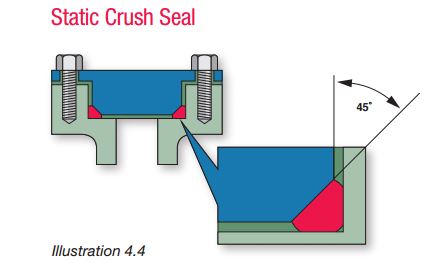

A crush seal (Illustration 4.4) is another type of static axial seal. The o-ring is crushed into a triangular shape groove. O-ring volume is usually 90-95% gland volume. The o-ring is permanently deformed and considered non-reusable.

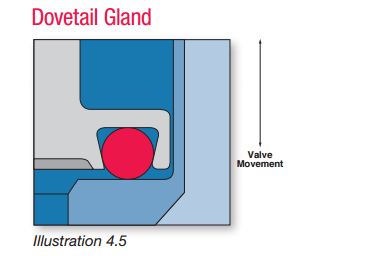

A Dovetail provides a retaining feature in a face seal gland. If the groove design in illustration 4.5 was of a standard face seal, the o-ring would fall out as the valve cycles up. The dovetail retains the o-ring in the groove. The o-ring is forced into the dovetail on installation, possibly tearing the o-ring. O-ring lubrication can minimize the chances of tearing.

Dovetail grooves result in a poor gland volume occupancy ratio. O-ring swell possibly caused by tolerances, extreme temperature, chemical compatibility, etc will not function well in a dovetail groove.

Static Radial Seals

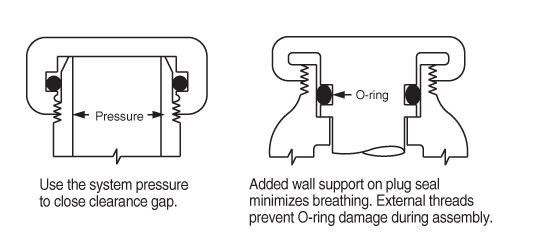

The sealing surfaces are perpendicular to the seal centerline in a radial seal orientation. The sealing surfaces are on the inner and outer diameter, aka the cross section of the o-ring. There are two variations of a radial seal. One is a piston seal where the groove is on the piston, illustration to the right. The second is a rod seal where the groove is on the bore, illustration to the left.

An axial seal orientation should be considered before a radial. Extrusion paths and tolerance stack up are simpler to control in an axial set up. Groove depth is the only compression variable. The plates are assumed to be parallel and flat having very little gap in between. In a radial configuration, there are tolerances on the bore diameter, groove diameter and piston or shaft diameters. The diametric gap between the bore and shaft or piston is inevitable. Poor tolerances will cause this gap to grow possibly allowing the O-Ring to extrude through it. Excessive tolerances on the bore and groove diameters will affect compression.

Have questions on static seals? Check out our Seal Types and Gland Design Table or contact our engineering team.